Disk Filter

1. Introduction to Disk Filter

Jieming Company was the first to introduce disk filtration technology into the Chinese market, and over the past ten years, this technology has been widely promoted and used. Nowadays, combining years of experience, our company has reformed and improved traditional technology, developing a new disk filtration system with independent intellectual property rights.

Utilizing multiple patented technologies, installation and usage are safer, more efficient, water-saving, space-saving, and require less routine maintenance. The filter element is designed without springs, cleverly utilizing incoming water pressure to compress the disk stack during filtration, greatly reducing the pressure requirements for backwashing.

The unique built-in duckbill valve ensures maximum water output during filtration while providing excellent reverse flow prevention during backwashing. The filter element skeleton is assembled in a modular manner, allowing flexible adjustment of the filter height according to design requirements, achieving the effect of adjusting the filtration area to meet different system matching requirements.

Abandoning the commonly used metal clamp design, the filter unit adopts a self-locking buckle combined with a specially designed sealing ring, making installation and disassembly of the filter unit shell simple and easy with good sealing effect.

Each filter unit is equipped with filtration and backwashing status indication devices as well as automatic exhaust devices, which can avoid water hammer damage while also improving the backwashing effect of the filter element.

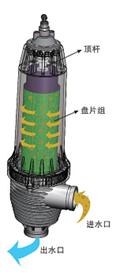

2. Working Principle of Disk Filter

【Operating State】

Incoming water enters the filter unit tangentially from the side inlet, and the incoming water pressure inside the chamber drives the diaphragm device on the upper part of the shell and presses down on the disk stack through the top rod. The disk stack is compressed to form a dense filter core, and impurities in the water are intercepted by the filter core. The filtered water then passes through the duckbill valve in the center of the filter core to the outlet at the lower part. As the diaphragm is pressed down, the red indicator cap on the upper part of the shell falls into the slot.

【Backwashing State】

During backwashing of the filter unit, the side inlet becomes a drainage port, and the diaphragm device loses its previous downward pressure. At this time, backwashing water enters from the outlet at the lower part. Due to the action of the duckbill valve, the backwashing water can only pass through four nozzles on the guide tubes to push up the filter press cap and diaphragm device, loosening the disk stack while spraying tangentially, causing the disks to rotate and flushing out the solids trapped on the disks. As the diaphragm device is pushed up, it the red indicator cap on the upper part of the shell to be pushed out, making it easy to see and judge the condition of the internal filter element from the outside. During backwashing, the automatic intake and exhaust valve on the upper part will automatically open, allowing air to enter the chamber, which helps improve the jet cleaning effect.

3. Application Scope of Disk Filters

Raw Water: Mechanical impurities, algae, bacteria, and organic matter filtration for surface water and groundwater.

Municipal Use: Raw water filtration; compliant filtration for sewage discharge; fountain water filtration in parks and landscaping.

Power Plants: Steam turbine cooling water filtration, full-flow and bypass filtration for cooling water.

Agriculture: Irrigation, drip irrigation water filtration.

Reverse Osmosis/Ultrapure Water: Pretreatment, membrane protection, resin trapper.

Metallurgy/Petrochemical/Mining/Medicine/Pulping/Papermaking/Central Air Conditioning: Full-flow and bypass filtration for circulating water; process water use.

High-salinity Water Filtration: Brackish water, seawater, saltwater filtration.

4. Product Features of Disk Filters

Precise Filtration: Different precision filter disks can be selected based on water use requirements, with specifications of 20μ, 50μ, 100μ, 130μ, and 200μ available.

Efficient Backwashing: High-speed and thorough backwashing can be completed in just around 20 seconds.

Fully Automatic Operation and Continuous Water Output: In the filter set, the backwashing process alternates in turns, and the working and backwashing states are automatically switched to ensure continuous water output with minimal system pressure loss.

Standard Design: Standard module system design allows users to choose as needed, with flexible variability and strong interchangeability.

Non-standard Design: Can flexibly utilize corner spaces, installed according to local conditions, with minimal space required.

Reliable Operation and Simple Maintenance: Almost no routine maintenance is required. Components are 100% factory tested and trial-run, require no special tools, and have few spare parts. Long Service Life: The high-tech plastic filter core is sturdy, non-abrasive, and non-corrosive. Proven by years of industrial use, the filtration and backwashing effects do not deteriorate over time.

5. Filtration Unit

The filtration unit adopts special ultra-low-pressure backwashing technology (SLP) and non-metal contact with water technology (NSM), enabling backwashing pressure to be as low as 1.2bar (17psi), effectively saving energy.

With non-metal technology, the treated water does not come into contact with metal, resulting in good internal corrosion resistance and suitability for seawater desalination or brackish water filtration.

Breathing valve technology allows for efficient backwashing, reducing backwashing time and water consumption.

Air check valve technology features no metal or rubber, excellent internal corrosion resistance, and anti-aging properties.

Centrifugal technology effectively enhances filtration and backwashing effects.

Self-locking quick-release technology enables convenient and efficient maintenance.

6. Technical Parameters of Disc Filter

Interface: Inlet 3" clamp connection; Outlet 3" clamp connection

Dimensions: mm, Outer shell diameter: Φ230, Unit height: 840, Maximum width: 265

Net weight per unit: 9.4kg

Material: High-performance reinforced engineering plastic molding

Optional filter discs: Green 50u, Red 100u, Yellow 200u

Working pressure: 0.2~0.8Mpa

Backwashing pressure: 0.15~0.8Mpa

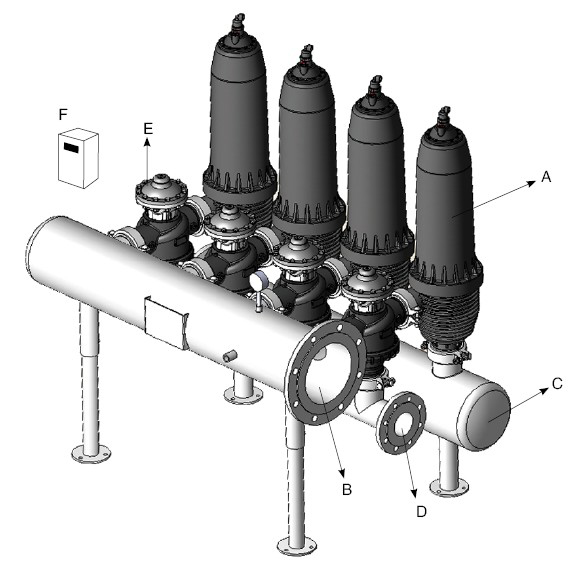

7. Outline Drawing of Disk Filter Equipment

Working pressure: 0.2~0.8Mpa

Backwashing pressure: 0.15~0.8Mpa

Operating temperature: < 60 ℃

PH value: 4~13

Number of filter units (A): 3~10 units

System backwashing method: Using the outlet water from other filter units to backwash each unit individually until all are completed.

Water inlet pipe (B): Made of stainless steel, with 6" ~8" flange connections

Water outlet pipe (C): Made of stainless steel, with 6" ~8" flange connections

Water outlet pipe (D): Made of stainless steel, with 3" flange connection

Backwashing valve (E): Made of plastic, with 3" clamp connection

System controller (F): Fully automatic dedicated controller with insulation rating of international standard IP65

Dimensions and weight: See attached sample

8. Design and Selection Instructions for Disk Filters

1) Classification of raw water quality for disk filters

Excellent water quality: City tap water, well water extracted from stable water-bearing strata;

Average water quality: Recirculating cooling water, surface water treated with sedimentation, and drainage effectively sedimented and fully biologically screened;

Poor water quality: Groundwater extracted from water-bearing strata with poor water quality, drainage with effective sedimentation but little or no biological treatment, surface water with a large amount of microbial reproduction;

Very poor water quality: Well water extracted from very dirty or iron- and manganese-rich wells, surface water affected by floods without sedimentation, and drainage without sedimentation and biological treatment. To ensure better operating conditions of the filtration system, pretreatment is required for Class D water quality to improve its grade by one level.

Different incoming water qualities have a significant impact on the operating cycle of the filter. Typically, when selecting a system, it should be ensured that the interval between system backwashes is not less than 1 hour.

2) Selection of filtration precision for disc filter

Choosing the filtration precision of the disc filter is crucial for ensuring its effective application in the entire water treatment system. The following table provides the recommended filtration precision for common centralized filtration applications.

Quality water treatment | 20μ |

Pretreatment of drinking water, production water, and nozzle protection | 50μ |

Circulating water filtration, pre-filtration for water treatment | 100μ |

Recycled water treatment, wastewater treatment | 200μ |

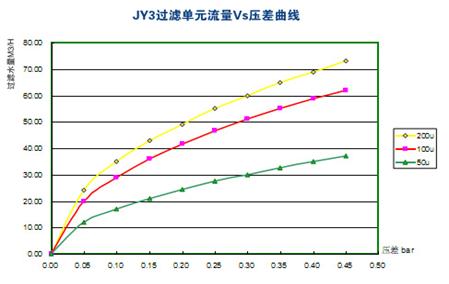

The quality of raw water, the required filtration precision, and the hourly water production capacity are the basis for selecting the disc filter system. The water production capacity of the filtration unit can be referenced by the flow rate/pressure drop curve.

3) Disk Filter Selection Chart

Raw water quality | Good water quality | General water quality | Poor water quality | Poor water quality | ||||||||

Filtration accuracy | 200μ | 100μ | 50μ | 200μ | 100μ | 50μ | 200μ | 100μ | 50μ | 200μ | 100μ | 50μ |

Filter Model | flow M3/H | flow M3/H | flow M3/H | flow M3/H | ||||||||

JY2-3 | 75 | 60 | 42 | 57 | 45 | 33 | 40 | 30 | 22 | 24 | 19 | 13 |

JY2-4 | 100 | 80 | 56 | 76 | 60 | 44 | 54 | 40 | 30 | 32 | 26 | 18 |

JY2-5 | 125 | 100 | 60 | 95 | 75 | 55 | 67 | 50 | 37 | 40 | 32 | 22 |

JY3-3 | ≤111 | ≤90 | ≤60 | ≤84 | ≤66 | ≤48 | ≤60 | ≤45 | ≤33 | ≤36 | ≤28 | ≤19 |

JY3-4 | 148 | 120 | 80 | 112 | 88 | 64 | 80 | 60 | 44 | 48 | 37 | 26 |

JY3-5 | 185 | 150 | 100 | 140 | 110 | 80 | 100 | 75 | 55 | 60 | 47 | 32 |

JY3-6 | 222 | 180 | 120 | 168 | 132 | 96 | 120 | 90 | 66 | 75 | 56 | 39 |

JY3-7 | 259 | 210 | 140 | 196 | 154 | 112 | 140 | 105 | 77 | 84 | 66 | 45 |

JY3-8 | 296 | 240 | 160 | 224 | 176 | 128 | 160 | 120 | 88 | 96 | 75 | 52 |

JY3-9 | 333 | 270 | 180 | 252 | 198 | 144 | 180 | 135 | 99 | 108 | 85 | 58 |

JY3-10 | 370 | 300 | 200 | 280 | 210 | 160 | 200 | 150 | 110 | 120 | 94 | 65 |

9.Disk filters may encounter some challenges during use, and the following are common problems and corresponding solutions:

1). Poor filtering effect: This may be caused by clogged filter discs, aging filter discs, or improper operating parameters. Solutions include regularly cleaning the filter cake, replacing the filter cloth, or adjusting operating parameters such as pressure, temperature, and flow rate.

2). Difficulty removing the filter cake: This may be due to the filter disc being too thick, the surface of the filter cloth being uneven, or improper operation. You can try adjusting operating parameters such as increasing the number of backwashing cycles or reducing the filtering pressure to help the filter cake detach smoothly.

3). Broken filter discs: This may be caused by sharp particles in the filtering medium or poor quality of the filter cloth. To solve this problem, you can consider replacing a more durable filter cloth or pretreating the medium to remove sharp particles before filtering.

4). Filter blockage: This may be due to a large amount of suspended matter or particles in the liquid, causing blockage inside the filter. Blockage can be prevented by increasing the number of backwashing cycles, increasing the filtering speed, or using a finer filter cloth.

5). Improper equipment maintenance: This may lead to decreased filter performance or equipment failure. Therefore, it is recommended to regularly maintain and service the equipment, such as cleaning the filter, replacing worn parts, etc., to ensure its normal operation and extend its service life.

Please note that the above problems and solutions are for reference only, and specific solutions may need to be adjusted according to actual conditions. During use, it is crucial to follow the operating manual, regularly inspect and maintain the disk filter to ensure stable operation and efficient filtering effect.